New Technology....

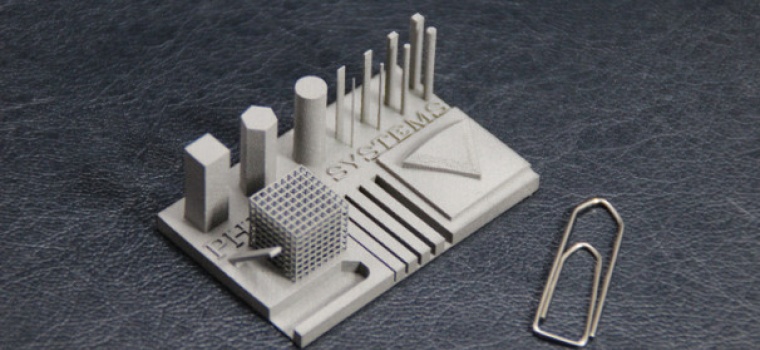

/GlenDee / MGI is making headway on 3D additive manufacturing. With our background in machining 3D metal printing is something to think about.

GlenDee / MGI is making headway on 3D additive manufacturing. With our background in machining 3D metal printing is something to think about.

Machined tapered walls

The product pictured uses several methods to measure quality. After a thorough review we have managed to reduce total touch time by approximately 15 hours in a normal production cycle. SPC allows us to monitor the quality of the product in a very predictable method. This eliminates the potential escapes and increases the overall AQL quantity. This product currently exceeds a Cpk of 2.35.

How a Highly Successful Military Aerospace

Manufacturer Achieved Success by Setting its Sights on Increased Productivity.

Story and photos by C. H. Bush, editor

Question: what’s in a nameplate? Answer: a highly successful military aerospace manufacturing company, if you do it right.

“My father, Glenn Grossman, founded Metalagraphics, Inc. (MGI) in a 2500-sq-ft building in 1975 to manufacture nameplates for the military and commercial aircraft industry,” says David Grossman, company vp, business planner and programmer. “But that was just the beginning. When he started MGI, my father was an air force veteran and a businessman with several years experience with a fortune 500 company. He was ambitious, he knew people in the industry, and he knew how to sell. The result is that today we operate from a modern, 28,000-sq-ft building, we have 56 employees and some of the most advanced manufacturing equipment available in the world.”

Copyright © 2019 - 2024 - GlenDee/MGI (A GlenDee Corporation) M: 805.523.2422 F: 805.523.9486 Email: info@mgius.com

Please participate in our customer satisfaction survey: Customer Satisfaction Survey